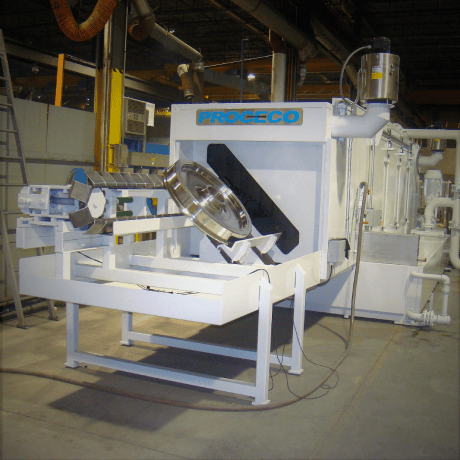

The PROCECO TYPHOON® MB is a heavy-duty power-spray belt parts washer designed for automatic processing and cleaning of heavily contaminated and/or heavy components. This inline conveyor washer cleans the railway wheels with the help of high-pressure spray jets of and heated aqueous solution.

Railway Wheel Washer

PROCECO offers integrated systems to wash railway wheels after machining.

The multi-stage cleaning process typically consists of a recirculating heated, high-pressure spray with a water-based cleaning solution containing a small percentage of alkaline detergent, followed by an optional rinse/rust inhibiting stage, followed by a blow-off/drying stage. A specially designed in-line, continuous-flow conveyor transports the wheels through the cleaning process. Optional inbound and outbound conveyance buffers connect the washer to your production environment.

Production rate : Up to 60 new manufactured wheels per hour.

CONTACT A SOLUTION EXPERT

PROCECO develops aqueous cleaning systems that go beyond cleaning, by seamlessly integrating a wide range of processes and features that dramatically improve your productivity and profitability.