How often will I need to replace the wash solution, and how will I know? This is a recurring question for every aqueous parts washer operator. Addressing it is always complex, as the answer can vary due to multiple factors.

Industrial parts washers are essential tools in the manufacturing process. They ensure that components are clean and meet the cleanliness requirements stipulated by manufacturers. In general, the dirtier the parts and the higher the volume of parts, the more frequently the solution will need to be replaced.

Every situation differs, and the chemicals used vary from one supplier to another, making it challenging to pinpoint an exact time for replacing the wash solution. Let’s examine the various factors that can help determine the right timing.

Cleaning Performance

A decrease in cleaning performance after titration signals the need to replace your cleaning solution. Over time, dirt, oil, and debris from previously processed parts contaminate the solution, causing it to lose its effectiveness. This can lead to parts not meeting cleaning requirements and to longer cleaning cycles if the solution is not changed. If you notice a decline in cleaning quality, it is better to replace the solution rather than extend the cleaning cycle.

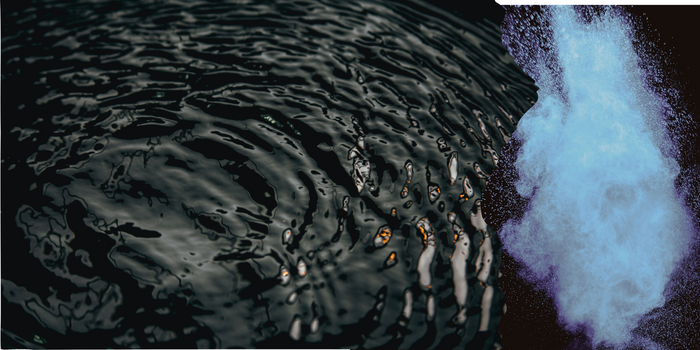

Visual Inspection

Regular visual inspection of your cleaning solution can provide insight into its condition. Check for changes in color or clarity, the presence of floating debris, or an excessive amount of oil on the surface after the washer has been inactive (e.g., between shifts or overnight). Observing these signs indicates that the solution needs changing.

pH Level

Monitoring the pH level of your cleaning solution is critical. As contaminants accumulate, they alter the pH balance. A significant shift can reduce cleaning effectiveness and, in some cases, even harm the parts being cleaned. Regularly testing and maintaining the pH within the recommended range ensures optimal performance. Maintenance personnel may test and adjust pH manually on a preventive schedule, or sensors installed on the washer may feed this information live to a central monitoring system.

Water Hardness

Water hardness can cause several undesirable effects. Evaporation of water does not remove existing minerals, and replenishing the solution with fresh water adds more. These accumulated minerals can react with soaps and detergents to form insoluble compounds, reducing the effectiveness of cleaning agents. As a result, effective cleaning may require higher chemical concentrations and longer cycles.

Foaming

Excessive foaming during the cleaning process can be a sign of contamination or degradation of the cleaning solution. Some foaming is normal during agitation or immediately after replacing the solution. It may also occur if the washer is run at lower-than-specified operating temperatures. However, if the washer is operating at the correct temperature and foam increases beyond normal, it may indicate unwanted contamination. Foam not only reduces cleaning efficiency but can also lead to equipment maintenance issues. If foaming becomes problematic, consider changing the solution.

Operating Costs

Companies often overlook rising operating costs as a sign to change the wash solution. An exhausted solution may require longer cleaning cycles to achieve acceptable results, leading to higher energy consumption and greater maintenance needs. In some instances, the parts may not meet the cleanliness requirements and require manual intervention, resulting in additional labor costs. Tracking these increased costs can help determine when it is more cost-effective to replace the solution.

Conclusion

In an industrial setting, maintaining the cleanliness and efficiency of parts washers is crucial for product quality and equipment longevity. Regularly changing your cleaning solution is essential to ensure optimal performance. Monitoring for signs of degradation such as reduced cleaning performance, visual changes, pH shifts, foaming, and rising operating costs will help determine the right time to refresh your solution. Frequent titration monitoring and maintaining a data log help predict when the cleaning performance will decrease and when it’s time to change the solution. By staying vigilant and proactive in maintaining both the washer and the cleaning solution, you can keep your industrial parts washer operating at its best, saving both time and money.

|

🔍 Not sure when to replace your cleaning solution? |

.jpg?height=400&name=Post%20Banner%20(4).jpg)