Wind Turbine Components

With over 48 years of cross-industry experience in manufacturing large parts washers that are both energy efficient and environmentally friendly, PROCECO has been the go-to partner for numerous OEM suppliers and MRO companies in the renewable energy sector. Our automated systems meet and exceed expectations in removing various contaminants such as oil, grease, machining debris, sealant, and dirt.

PROCECO's capabilities in manufacturing custom-built, large industrial parts washers that will safely handle your largest components have saved time and money for many operators and service centers alike.

In addition, by providing fully integrated, closed-loop washing systems, PROCECO has enabled companies to meet the increasing demand in volume while minimizing manual intervention and environmental footprint.

Wind Turbine Components

PROCECO's expertise in wind turbine cleaning includes bearings, generators, gearboxes, and other associated components that are cumbersome, heavily contaminated, and difficult to clean.

With decades of experience in manufacturing and designing custom parts washers for specific applications across multiple industries, PROCECO offers robust and reliable washers for your wind turbine components.

Our engineers and experts work as an extension of your team to build a suitable washer that will align with your processes and meet your expectations.

Wind Turbine Components

PROCECO's expertise in wind turbine cleaning includes bearings, generators, gearboxes, and other associated components that are cumbersome, heavily contaminated, and difficult to clean.

Our engineers and experts work as an extension of your team to build a suitable washer that will align with your processes and meet your expectations.

Extensive Know-How With Large Components

Over the years, we’ve handled just about every cleaning problem that railway professionals like you have faced!

Rail & Mass Transit Parts Washers

Since 1975, PROCECO has developed an extensive expertise in water-based part cleaning and surface treatment processes. This broad experience enables us to provide unmatched value in the design, manufacture and support of your PROCECO systems.

Rail & Mass Transit Applications

- Parts Cleaning in the Rail & Mass Transit Industry

-

Parts Cleaning in the Rail & Mass Transit Industry

Since 1975, PROCECO has developed a complete line of multi-stage, automatic degreasing and washing plants that are engineered to meet the demanding rail and mass transit maintenance processes. These aqueous parts washers deliver fast, high-quality cleaning while reducing chemical and labor costs.

Rail & Mass Transit Resources

BEARINGS & COUPLINGS

GENERATOR

BRAKE

HIGH-SPEED SHAFTS

LOW SPEED SHAFT

PINION GEAR

GEARBOX

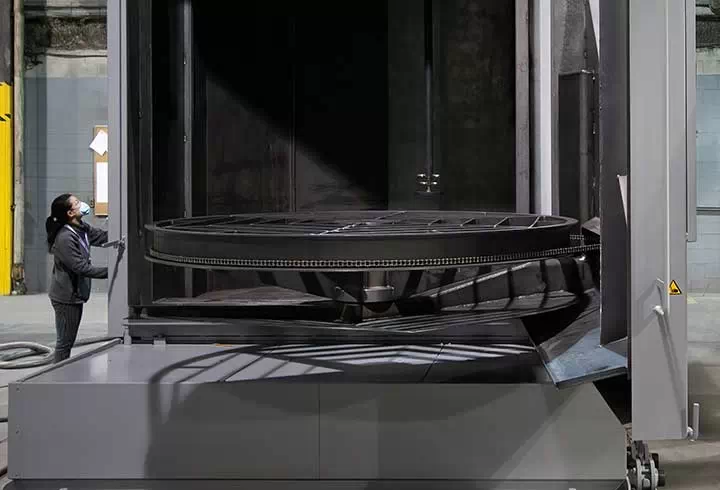

WIND TURBINE PARTS WASHER

TYPHOON®-HD

THE TYPHOON®-HD ADVANTAGE

Heavy-duty steel construction (stainless-steel option)

Multi-stage automated process for efficiency and flexibility

Recirculating wash and rinse stages to conserve energy, detergent, and water

Thousands of different configurations and pre-engineered optional features

The power-spray principle produces high-quality and high-speed cleaning

Low energy cost – fully insulated systems

Environmentally friendly – aqueous cleaning technology

No health hazard to workers

CONTACT A SOLUTION EXPERT

PROCECO develops aqueous cleaning systems that go beyond cleaning, by seamlessly integrating a wide range of processes and features that dramatically improve your productivity and profitability.