Industrial Parts Cleaning

PROCECO industrial parts washers use recirculating hot water and environmentally safe detergents to provide the cleaning action required for your specific application.

Cost-Effective Industrial Parts Washers

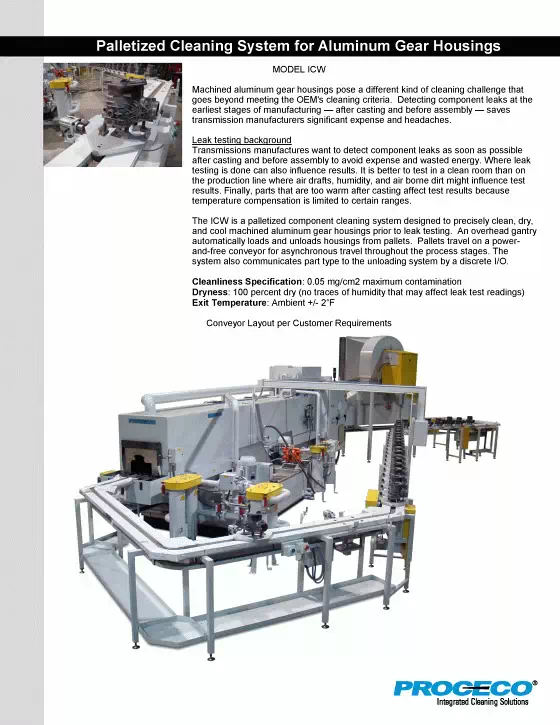

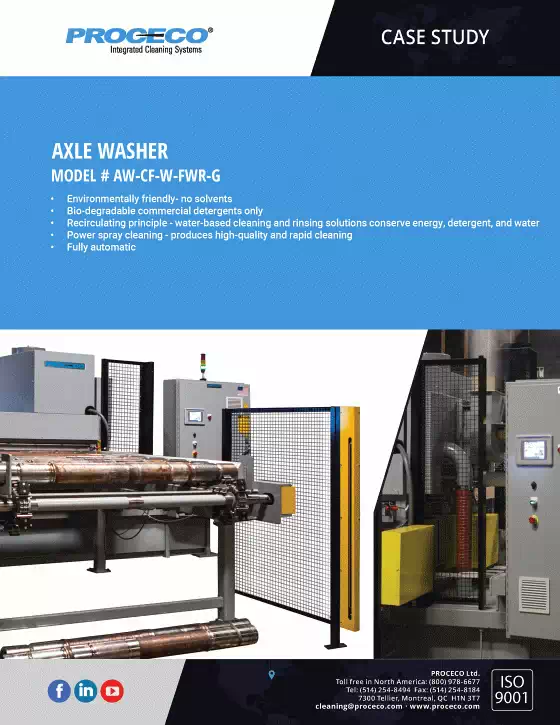

Rather than sell you a generic, "canned" parts cleaning solution, our value goes into understanding your specific cleaning needs and then providing you with a system that produces clean parts cost-effectively. PROCECO recognizes that the development of a repeatable cleaning process extends beyond the technical aspects of an industrial parts washer. PROCECO is committed to delivering reliable and long-lasting parts washers and cleaning equipment that optimize your horsepower, heating, and chemical energy needs to reduce total life cycle costs.

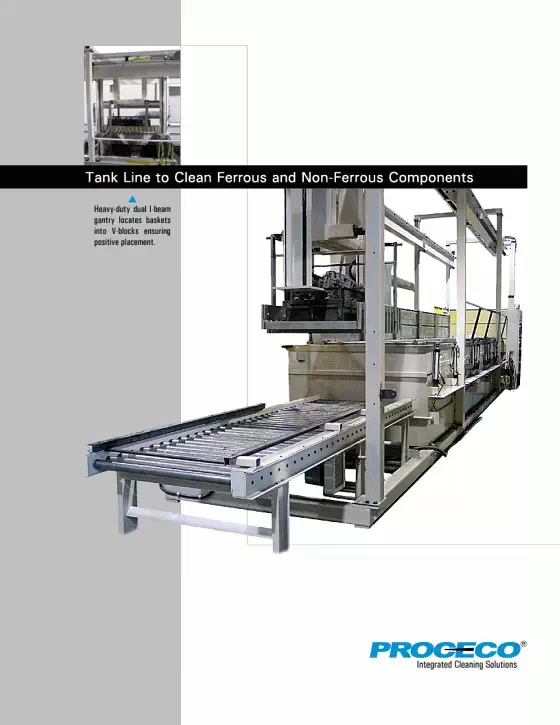

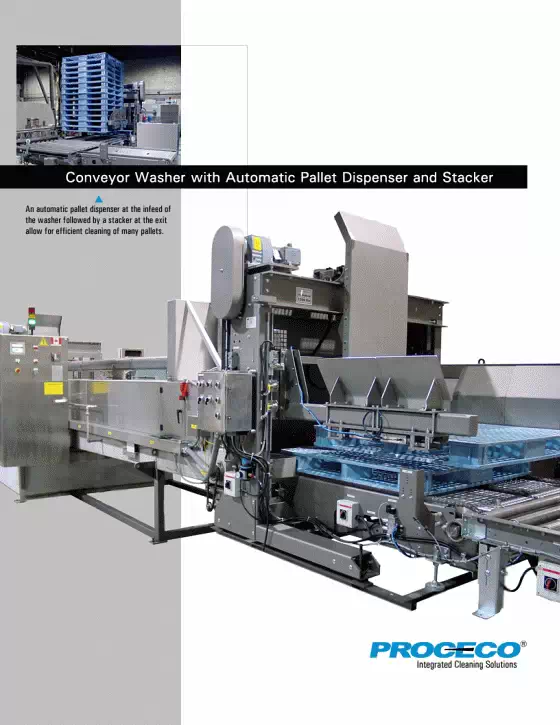

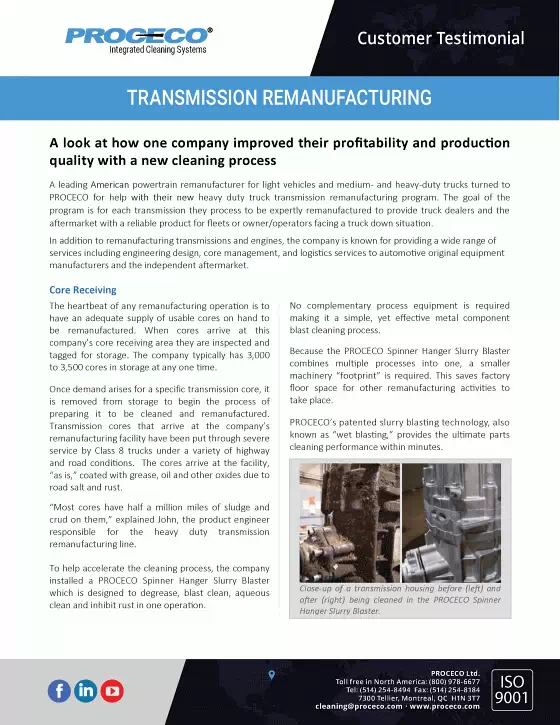

Our industrial parts washers are designed for a wide range of parts cleaning operations, from precision metalworking processes to remanufacturing operations. We will help you select the most effective cleaning equipment configurations and chemistries to meet your requirements, whether it be to simply remove metalworking fluids, metal chips, and abrasives—to more challenging applications such as the removal of grease, grime, baked-on carbon deposits, and even paint.

PROCECO has designed many systems for OEM manufacturers or companies that perform maintenance and overhaul. In the global aerospace industry, PROCECO has engineered and supplied over 500 parts washers and cleaning systems, each of which far exceeds conventional design standards. Each system is custom-engineered for specific workpieces and processes to suit your requirements.

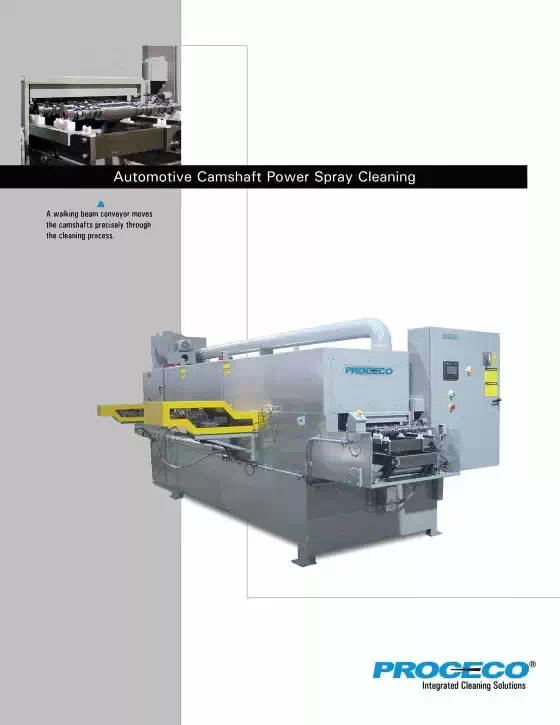

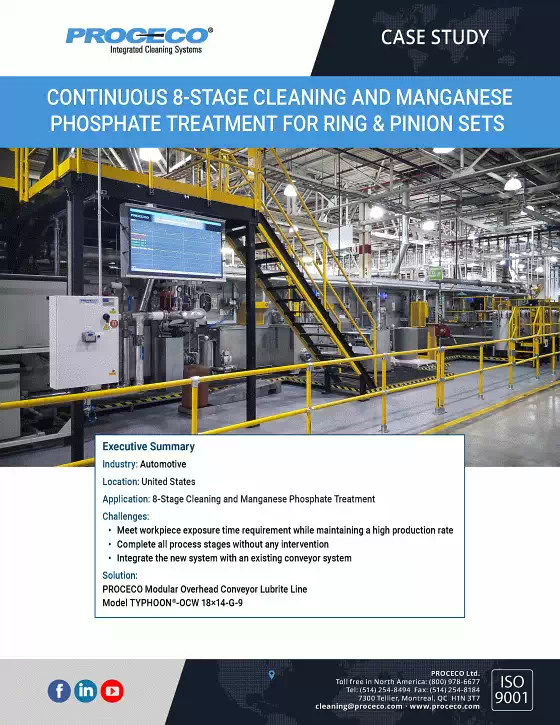

Tier 1/Tier 2 automotive component manufacturers and OEM's around the world depend on PROCECO hydro-deburring systems to increase their productivity and profitability, as well as to improve the quality of their products. In the global automotive industry, PROCECO has engineered and supplied over 2,000 parts washers and cleaning systems, each of which far exceeds conventional design standards.

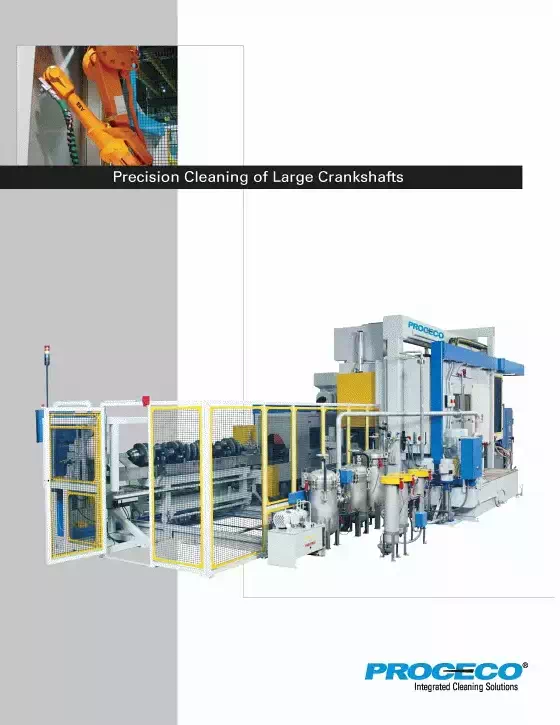

Dealer maintenance centers, rebuilding depots, Tier 1/Tier 2 off-highway equipment component manufacturers and OEMs around the world have relied on PROCECO cleaning systems to increase their productivity, profitability, and product quality. In the global heavy machinery industry, we have engineered and supplied over 1,000 parts washers and cleaning systems, each one far exceeding conventional design standards.

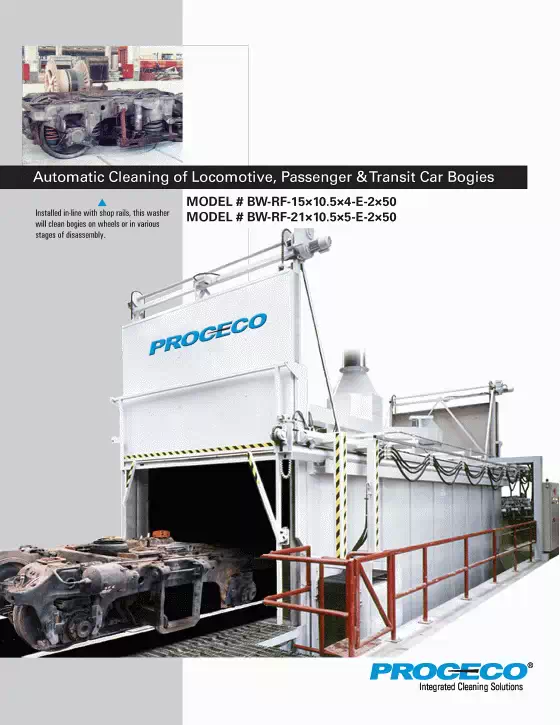

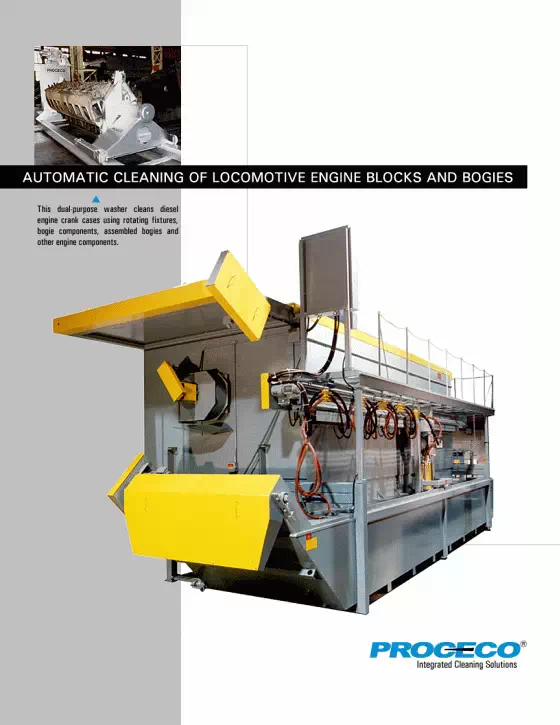

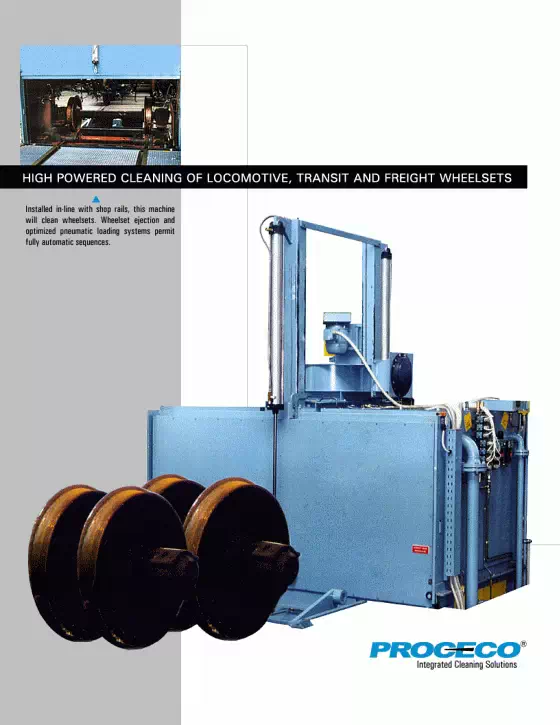

PROCECO has developed a complete line of multi-stage, automatic degreasing and washing plants that are engineered to meet the demanding rail and transit maintenance processes. These aqueous parts washers deliver fast, high-quality cleaning while reducing chemical and labor costs. PROCECO can also custom-design systems tailored to any of your specific needs

PLEASE CLICK ON THE FOLLOWING CLEANING AND DEGREASING APPLICATIONS AND COMPONENTS CASE STUDIES

CONTACT A SOLUTION EXPERT

PROCECO develops aqueous cleaning systems that go beyond cleaning, by seamlessly integrating a wide range of processes and features that dramatically improve your productivity and profitability.