Parts Washers and Cleaning Systems for Aviation and Aerospace

With over 100 customers in the aerospace and aviation industries, our experience enables us to design flexible cleaning systems that significantly reduce your operating costs and help you reach a high production level. We have integrated more than 500 industrial parts washers and cleaning systems for our aerospace clients, including MRO, Tier 1 and Tier 2 aerospace component manufacturers, and OEMs.

Whether you manufacture aircraft engine components or provide maintenance, repair, and overhaul (MRO) services, PROCECO offers a wide selection of aqueous, single- or multi-stage parts washer models to meet your parts cleaning needs. By integrating everything from automated parts handling and DI (deionized) water production to wastewater treatment, these industrial cleaning systems are designed to deliver high quality and repeatable cleaning results while reducing chemical and labor costs.

Trust PROCECO's extensive experience to supply you with tailored cleaning systems, from design concept to turnkey installation, to degrease, clean, and dry your aircraft components.

HIGH-QUALITY AND REPEATABLE CLEANING RESULTS

Whether you're cleaning small parts or extremely large components, we have the engineered system to meet your toughest cleaning needs.

AEROSPACE TYPICAL COMPONENTS

For over 47 years, PROCECO has designed many industrial cleaning solutions for OEM manufacturers or companies that perform maintenance and overhaul. In the global aerospace industry, PROCECO has engineered and supplied over 500 parts washers and cleaning systems, each of which far exceed conventional design standards. Each cleaning system is custom engineered for specific workpieces and processes to suit your requirements.

AEROSPACE PARTS WASHERS

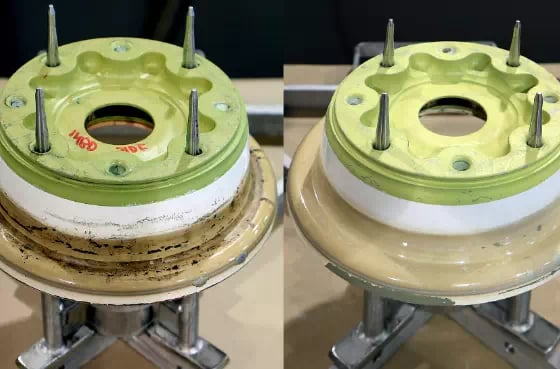

Aircraft Wheel Washers

- TYPHOON®-AWW Aircraft wheel washer designed to remove grease, rubber residues, dirt, and dust from wheel hubs

- Turntable Cabinet Washer for Aircraft Wheels The PROCECO TYPHOON®-HD turntable washer configured for aircraft wheels cleans multiple wheel hubs loaded on a fixture or directly placed on the turntable

Fluid Penetrant Inspection Systems

AVIATION & AEROSPACE APPLICATIONS

- Aviation & Aerospace Parts Cleaning

- Fluorescent Penetrant Inspection

- Surface Treatment

-

Aviation & Aerospace Parts Cleaning

Since 1975, PROCECO has designed over 500 cleaning systems for OEM manufacturers or companies that perform aircraft maintenance and overhaul. Each system is custom-engineered for specific workpieces and processes to suit your requirements. -

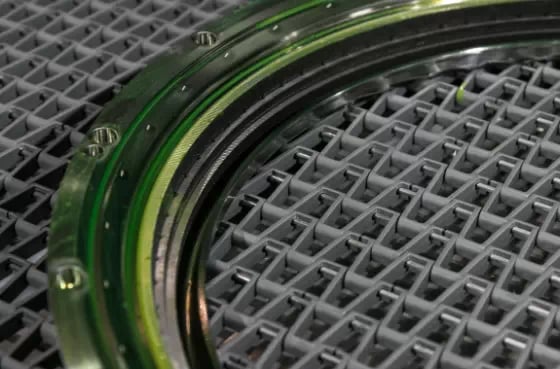

Fluorescent Penetrant Inspection

PROCECO's Fluorescent Penetrant Inspection processing equipment consists of multi-stage immersion systems that integrate aqueous parts cleaning, surface preparation, and surface treatment in one automated process. PROCECO's automated FPI systems are ideal for revealing flaws, cracks and fatigue signs, and for exposing metal grain structure on the surfaces of aerospace turbine engine components. The systems can also be engineered for other liquid penetrant inspection processes, such as Blue Etch Anodize (BEA) and chemical etch inspection. -

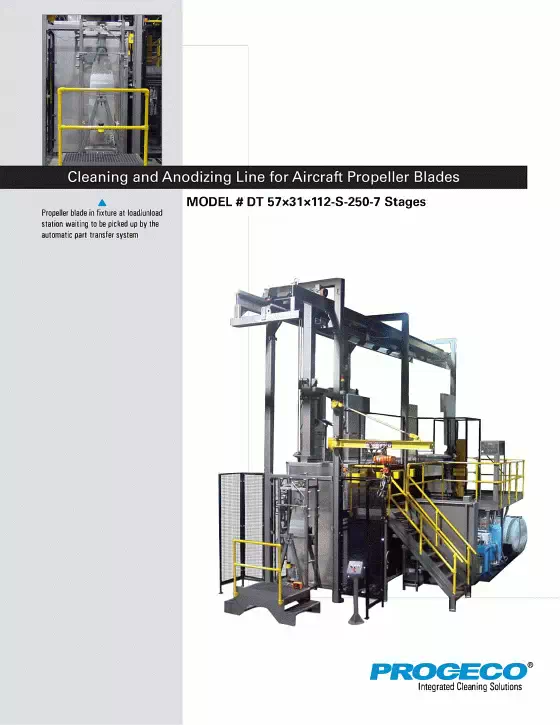

Surface Treatment

PROCECO surface treatment systems cover a wide range of processes: acid etch, anodizing, blue etch anodizing, degreasing, phosphating, zinc nickel alloy, hard chrome, and chromate conversion coatings.

TESTIMONIALS

“We really enjoy working with PROCECO’s team members, each time they visit our factory they are treated like family! They have done an outstanding work […]! We also want to thank all of you for your continued support getting our four PROCECO machines up and running!”

Greg H.

“...I am confident that we made the right decision in selecting PROCECO for this project. We will be looking forward to working with PROCECO in the future.”

Jason Rash

“...With the productivity gains achieved with your wash systems since installation in 1998, we have significantly reduced our product turn time and relieved the "bottleneck" that plagued this area previously.”

Alan M. Shearer

“...I've seen this AWW during my shop visit in Vienna, Austria and I was very impressed. I got a lot of positive feedback from the shop personnel regarding the reliability and customer satisfaction of this AWW...”

Gundolf Flemming

“...major improvements in the cleaning of bearings have been achieved using the high-pressure, water-based systems developed by PROCECO.”

Timo Nellemose

“...ST Aerospace Solutions, former SAS Component, located in Copenhagen, Denmark, have been a more than satisfied customer at PROCECO, Montreal, Canada.”

Thomas B Pedersen

“...From the design inception through the installation and run-off at our facility, your professionalism has been matched only by the effectiveness of the machine you built. The success of our entire project rested on our ability to get our parts clean enough for inspection”

Michael Campbell

Our TRUSTED PARTNERS

IN THE AEROSPACE INDUSTRY

AVIATION & AEROSPACE RESOURCES

CONTACT A SOLUTION EXPERT

PROCECO develops aqueous cleaning systems that go beyond cleaning, by seamlessly integrating a wide range of processes and features that dramatically improve your productivity and profitability.