Surface Treatment Equipment

PROCECO offers a broad range of systems to provide innovative engineered solutions that streamline metal surface treatment processes, dramatically increase productivity, and improve quality.

Fully Automated Surface Treatment Systems

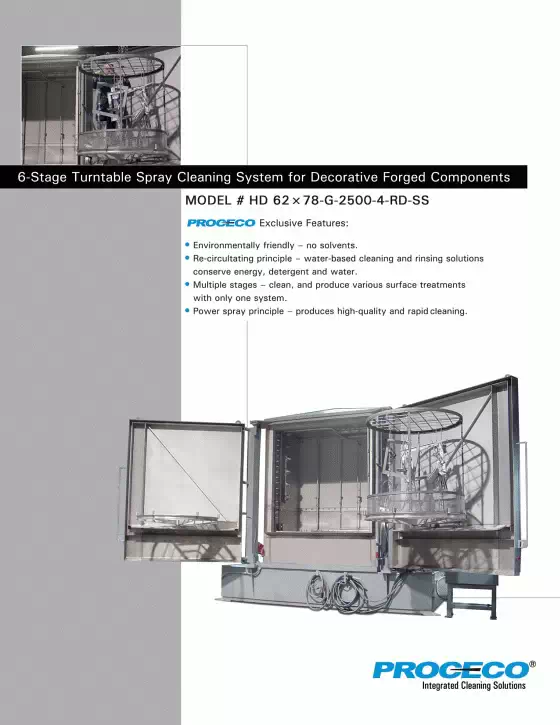

Our value is in understanding your chemical process, cleaning, and production needs to offer fully integrated systems with full automation and production traceability. Typical systems feature computer-controlled transfer hoists, immersion, power spray, mechanical agitation, ultrasonics, and a variety of part-positioning solutions, from workpiece rotation to rotary drums.

Understanding that most surface treatment systems utilize a tremendous amount of rinse water in the process, PROCECO has developed rinse-water recycling systems and drag-out reduction techniques to significantly reduce water use.

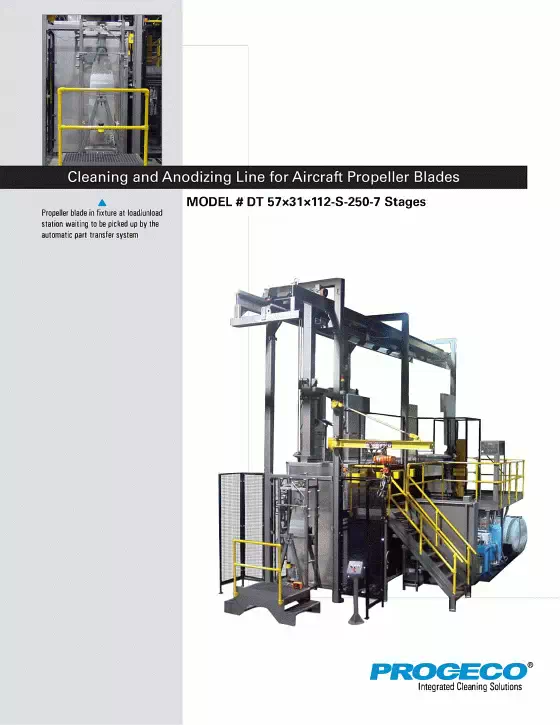

PROCECO surface treatment systems cover a wide range of processes: Acid Etch, Anodizing, Blue Etch Anodizing, Degreasing, Phosphating, Zinc Nickel Alloy, Hard Chrome, and Chromate Conversion Coatings.

PROCECO has designed many surface treatment systems for OEM manufacturers or companies that perform maintenance and overhaul. In the global aerospace industry, PROCECO has engineered and supplied over 500 parts washers and cleaning systems, each of which far exceeds conventional design standards. Each system is custom-engineered for specific workpieces and processes to suit your requirements.

PLEASE CLICK ON THE FOLLOWING SURFACE TREATMENT APPLICATIONS

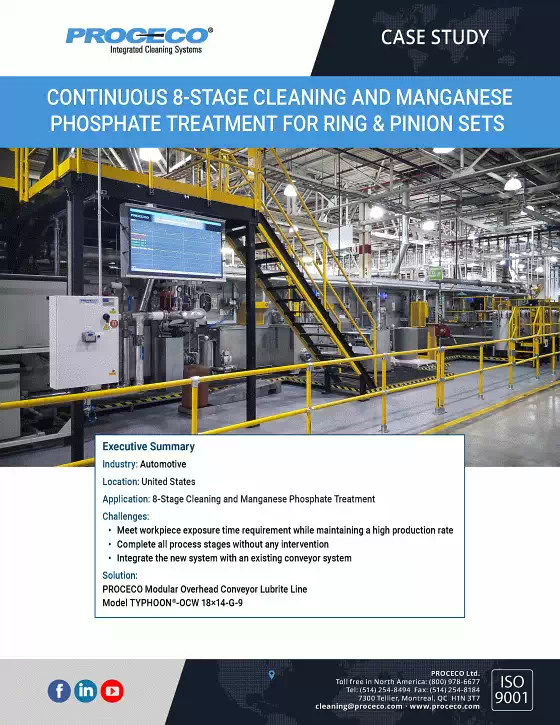

Tier 1/Tier 2 automotive component manufacturers and OEM's around the world have relied on PROCECO cleaning systems for nearly five decades to increase their productivity, profitability, and product quality. PROCECO has engineered and supplied over 2,000 parts washers and cleaning systems to automotive manufacturers worldwide. Each system has far exceeded conventional design standards.

PLEASE CLICK ON THE FOLLOWING SURFACE TREATMENT APPLICATIONS

Dealer maintenance centers, rebuilding depots, Tier 1/Tier 2 component manufacturers, and OEMs around the world depend on PROCECO surface treatment systems to increase their productivity and profitability, as well as to increase the quality of their products. In the global heavy machinery industry, we have engineered and supplied over 1,000 parts washers and cleaning systems, each one far exceeding conventional design standards.

PLEASE CLICK ON THE FOLLOWING SURFACE TREATMENT APPLICATIONS

CONTACT A SOLUTION EXPERT

PROCECO develops aqueous cleaning systems that go beyond cleaning, by seamlessly integrating a wide range of processes and features that dramatically improve your productivity and profitability.