Automated Immersion Systems

Cleaning & Surface Treatment Line

Key benefits

- Custom-engineered for specific applications and workpieces

- Combines surface cleaning, preparation and treatment in one automated process

- Automated parts transfer that assures high throughput and process consistency

- Ultrasonics, agitation, turbulation rotation, and spray cleaning can be integrated

- Energy-efficient designs

- Turnkey installations

Overview

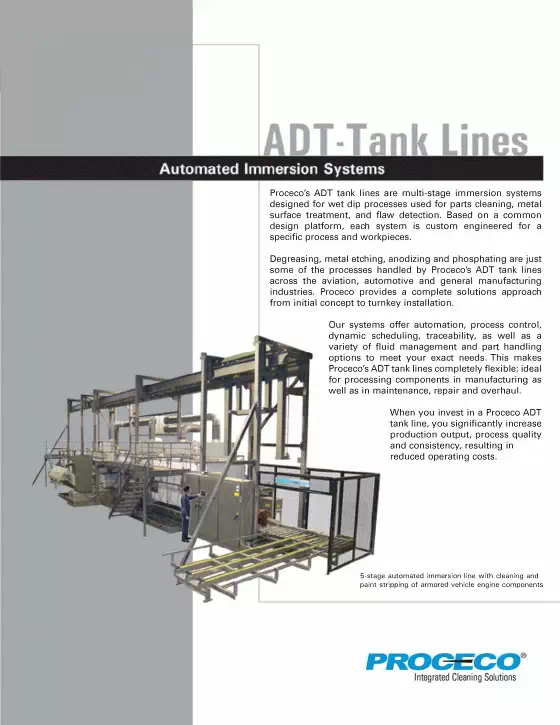

PROCECO's ADT tank lines are multi-stage systems designed for aqueous-cleaning, pre-treatment, and surface treatment by wet dip processes. Each immersion system is custom-engineered for specific applications and workpieces.

PROCECO's ADT immersion lines accommodate a range of processes in the aviation, automotive, and general manufacturing industries, including parts degreasing, anodizing, chemical pickling, and manganese phosphate conversion coating (Lubrite®). PROCECO provides complete solutions from initial concept to turnkey installation.

Tailored to your exact needs, our systems offer automation, process control, dynamic scheduling, and automatic part transfer hoists. Additional processes, such as ultrasonics, agitation, turbulation rotation, and spray cleaning can be integrated into any immersion system to enhance parts cleaning and surface treatment. This flexibility makes PROCECO's ADT immersion lines ideal for any parts manufacturing environment.

When you invest in a PROCECO ADT immersion tank line, you can increase your production output, improve the quality and consistency of your parts cleaning processes, and at the same time significantly reduce your operating costs.

- Specification sheets

- Download resources

- Videos

-

Work HeightWork Height42”48”56”60”72”84”108”

-

TESTIMONIALS

“We really enjoy working with Proceco’s team members, each time they visit our factory they are treated like family! They have done an outstanding work […]! We also want to thank all of you for your continued support getting our four Proceco machines up and running!”

Greg H

“With the productivity gains achieved with your wash systems since installation in 1998, we have significantly reduced our product turn time and relieved the "bottleneck" that plagued this area previously...”

Alan M. Shearer

CONTACT A SOLUTION EXPERT

PROCECO develops aqueous cleaning systems that go beyond cleaning, by seamlessly integrating a wide range of processes and features that dramatically improve your productivity and profitability.