Parts washers use electric, gas, or steam heating. Natural gas offers advantages over electric: reduced electrical load, faster heating, enhanced reliability, fuel flexibility, and lower operating costs. Electrical limitations affect equipment size. Our forced-air gas burners optimize heat transfer efficiency. While NG heating has higher upfront costs, it is more cost-effective in the long run.

COST FACTORS THAT INFLUENCE THE PRICE OF A PARTS CLEANING EQUIPMENT

When it comes to sourcing a parts washer, many options are available. Like most capital equipment, the price range can vary significantly from one option to another, even for simple parts cleaning applications.

Factors such as machine size and capacity, construction materials, assembly components, and customer service quality all play a role. This blog will help you choose the best equipment for your needs by explaining how various factors affect the price of parts cleaning equipment.

Size and Capacity

The size and rated capacity of equipment significantly impact the price you pay for it. Generally, larger equipment with higher capacity is more expensive because it requires more material and robust components like pumps, gear drives, and turntable bearings.

However, simply choosing a parts washer based on size and capacity doesn't mean it's the best machine overall. For example, there can be a significant difference between two parts washers using the same rated pump capacity. The proper design and configuration of spray manifolds ensure the optimal distribution of flow and spray impact on parts.

Solution tank size is also important to prevent excessive circulation and turbulation, resulting in excess foaming and insufficient settling of dirt and debris carried away from the workpieces. Smaller solution tanks need more frequent cleanouts since the cleaning solution has a limited capacity to remove and encapsulate grease and oil.

Frequent tank clean-outs require more machine downtime and possibly increased detergent costs. To avoid this, the tank volume should be 2 to 4 times the rated pump flow per minute, especially for heavy-duty cleaning with stubborn soils and high soil loads that require larger tanks. This generic rule means that a small parts washer with a 100 USG tank and a 90 USGPM pump will not perform as well as it should because these two specifications are not a good match.

Spraying the cleaning solution onto the workpieces accounts for much of the heat loss in a parts washer. The wash temperature will drop throughout the process if the washer has insufficient heat capacity. There is a big difference between reaching a set temperature and maintaining it during the cleaning process. It is essential to understand the required heating power when purchasing a parts washer, something that may not be known with an “off-the-shelf” washer.

Another important factor for turntable parts washers is the load capacity. When comparing two washers with similar load capacities, one must inquire about the load rating. If the load rating is based on a centric load, an off-center load will cause extra bending stress on the turntable cross members, potentially resulting in early wear on the bearings.

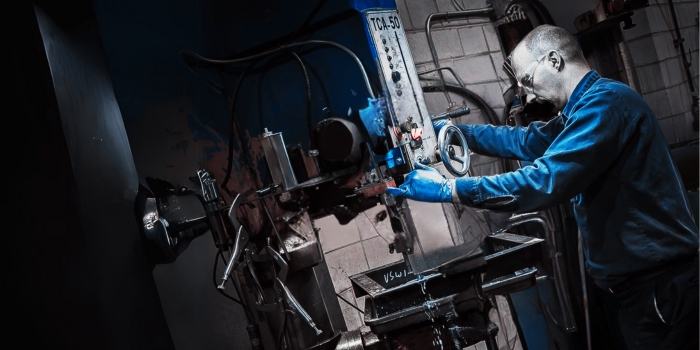

Materials and Construction

Equipment cost is affected by the materials used. Using higher-quality and more durable materials may be more expensive, but results in longer-lasting equipment.

Sourcing material from trusted and renowned sources such as mil-certified steel by ASTM standards is essential. Using a thicker plate, such as 11 gauge instead of 14 gauge, increases equipment durability in an industrial environment.

Following state-of-the-art assembly practices requires a skilled workforce, increasing labor costs. An example can be the welds made according to AWS standards that will ensure the machine will last many years. The tank and cabinet configuration is another factor. Having a cabinet with an integral floor will give more rigidity to the machine and represents an indispensable safety feature as it prevents contact with hot wash solution. The cabinet floor also prevents unintended tools or small parts from falling into the solution tank, protecting the pump and heating elements.

Components

Similar to the materials used, the component quality in parts washers will influence the cost. Using premium components from reliable suppliers provides peace of mind and ensures that replacement parts are readily available when needed.

The pump is the heart of your parts washer and the most important component. High-efficiency pumps rated for heavy-duty cleaning are paramount to the reliability of the parts washer. Getting the best performance out of the pump also requires adapted plumbing and even more heating capacity as mentioned above. It can also increase the cost of electrical controls when a soft starter or variable frequency drive is needed for higher horsepower pumps.

Industrial-rated controls that meet stringent safety regulations (i.e., CE, CSA, and UL) are key to ensuring the safety of personnel and the longevity and reliability of the equipment. Just as important is an electrical enclosure, wiring, and conduits, which are electrical code compliant for industrial use. An NEC-compliant electrical enclosure is a standard at PROCECO and should be for all equipment installed in a factory. Since the electrical enclosure and components represent a large portion of a parts washer's cost, some manufacturers might see an opportunity to cut costs by avoiding the NEC code, which could be very costly in equipment downtime or cause serious injury.

Service and Support

The quality and availability of service and support can also affect the price of your parts washer purchase. Equipment with a minimum one-year warranty and regular maintenance is a cost that will provide peace of mind and lower long-term operating costs. A team of cleaning experts will ensure you buy the right equipment to meet your cleaning requirements. Tailored equipment versus off-the-shelf equipment is likely to be more expensive; however, with the sound advice of a cleaning expert, the return on investment will be much higher.

In short, it is essential to consider many factors when purchasing a parts washer. Analyzing the machine's specifications and asking questions will ensure you get the most out of your investment.

Schedule a free consultation with the PROCECO team today.

.webp?height=400&name=Banner%20Cost%20that%20influence%20(700%20x%20350%20px).webp)