Industrial parts washing machines play a vital role in numerous manufacturing processes by upholding the cleanliness and effectiveness of parts and components. To maintain the seamless operation of these machines, it's imperative to promptly identify and resolve maintenance issues. In this blog, we will discuss some key tips on how to spot maintenance issues on parts washers, helping you avoid costly downtime and ensure the longevity of your equipment

HOW TO SPOT MAINTENANCE ISSUES ON INDUSTRIAL PARTS WASHING MACHINES

Industrial parts washing machines play a vital role in numerous manufacturing processes by upholding the cleanliness and effectiveness of parts and components. To maintain the seamless operation of these machines, it's imperative to promptly identify and resolve maintenance issues. In this blog, we will discuss some key tips on how to spot maintenance issues on parts washers, helping you avoid costly downtime and ensure the longevity of your equipment

Poor Cleaning Results

The primary purpose of an industrial parts washing machine is to clean parts effectively. When you observe a drop in cleaning effectiveness, it's a clear signal of a maintenance issue. Several factors, such as blocked or misaligned spray nozzles, worn-out filters, or malfunctioning pumps, can result in subpar cleaning outcomes. To uphold peak performance, conduct routine inspections and maintenance on these elements, replacing them as needed.

Reduced Efficiency

A sudden reduction in the efficiency of your parts washing machine is a sure sign of maintenance issues. This can manifest as increased cycle times, increased energy consumption, increased cleaning solution consumption, or an inability to reach desired cleaning results. To troubleshoot and address efficiency problems, inspect the machine's nozzles, heating elements, pumps, and filtration systems, and test chemical concentrations regularly.

Machine Down for Repairs

One of the most evident consequences of poor maintenance is the increased downtime of machines. When your equipment frequently requires repairs, it brings production to a standstill. This downtime directly hinders your company's capacity to meet orders, and the longer a machine is down, the more money you're losing.

Unusual Noises

One of the most apparent signs of maintenance issues in parts washers is the presence of unusual noises. These machines typically run relatively quietly, so any sudden increase in noise level or the emergence of new sounds can indicate problems. Common issues that may lead to unusual noises include misaligned belts, damaged bearings, or loose components. When the machine is making unusual or unfamiliar sounds, address them immediately

Error Codes and Malfunctions

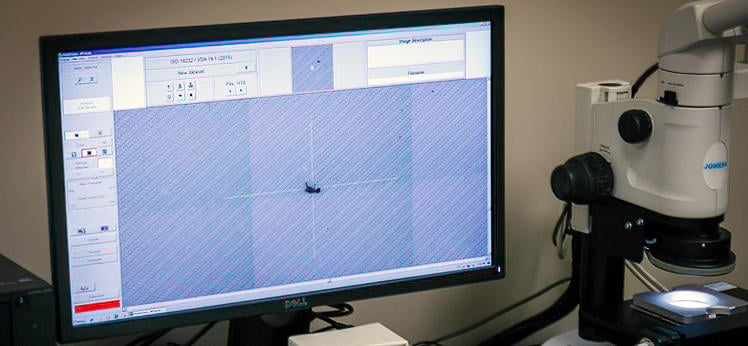

Most industrial parts washer machines have diagnostic systems that display error codes when issues arise. Familiarize yourself with these error codes and consult the machine's manual to identify the problem accurately. Addressing error codes promptly can prevent further damage and ensure the machine's reliability. Regularly check the Error Message History during routine maintenance to catch problems early.

Leaking Fluids

A noticeable sign of a maintenance issue is leaking fluids around the machine. Parts washers use various cleaning detergents and water; leaks can arise from damaged hoses, seals, or connectors. Such leaks not only reduce the machine's efficiency but can also pose safety hazards. Regularly check for any signs of fluid leakage and promptly replace or repair damaged parts to prevent more extensive issues

Let's explore the primary maintenance types and their associated advantages:

Preventive Maintenance: Regular cleaning, inspection, lubrication, and timely filter changes (including bag, cartridge, air inlet, and oil) are crucial in maintaining the machine's uptime. The benefits include:

Reduced Downtime: Preventive maintenance can be scheduled during periods of low demand or downtime, minimizing disruption to regular operations while minimizing the risk of unexpected breakdowns, and ensuring a more consistent workflow.

Extended Lifespan: Regular care helps prolong the life of your machine, saving on replacement costs.

Predictive Maintenance: Utilizing data from amperage readings, pressures, temperature, and chemical consumption, to monitor and predict issues in advance offers significant advantages:

Enhanced Efficiency: By identifying potential problems early, you can schedule maintenance when it's most convenient, reducing disruption.

Cost Savings: Predictive maintenance can lower overall maintenance costs, as it avoids costly emergency repairs.

Corrective Maintenance: Reactive responses are essential when issues arise. The benefits include:

Quick Issue Resolution: Immediate troubleshooting and prompt repairs ensure minimal downtime and prevent minor issues from escalating into major problems.

Production Continuity: Corrective maintenance plays a pivotal role in sustaining uninterrupted operational continuity, particularly when confronted with unforeseen challenges.

Overhaul or Refurbishment: Periodic, thorough examinations and part replacements provide multiple benefits:

Restored Performance: An overhaul restores your parts washer's performance, often making it as good as new.

Long-Term Savings: Instead of frequent minor repairs, overhauls offer a cost-effective, long-term solution.

In a competitive business environment, spotting maintenance issues is crucial for preventing downtime, ensuring optimal performance, prolonging the machine's lifespan, and providing a safer work environment. Subpar maintenance practices that result in frequent machine breakdowns are a burden no company can afford.

Neglecting your equipment carries consequences affecting your finances, operations, and safety. By implementing effective maintenance strategies, you can ensure the smooth operation of your machines, decrease downtime, cut repair expenses, and, in the end, secure your business's financial health. Remember that a properly maintained machine isn't merely an asset; it serves as a competitive advantage and plays a part in creating a cleaner and safer workplace.

Be sure to avoid costly downtime. Ensure the continuous operation of your parts washer by stocking up on Proceco-approved spare parts today! We keep most standard components in stock and ready to ship for minimal downtime.

Reach out to us without delay to explore our extensive range of Proceco-approved spare parts for your parts washer and keep your operations running smoothly.

Schedule a free consultation with the PROCECO team today.

%20(1).webp)