RESOURCES

At PROCECO, we produce high-quality collateral and tools to educate you about the various cleaning methods available and to help in your decision-making.

Filters

Resource Type

Industry

Machine Type

Show

CONTACT A SOLUTION EXPERT

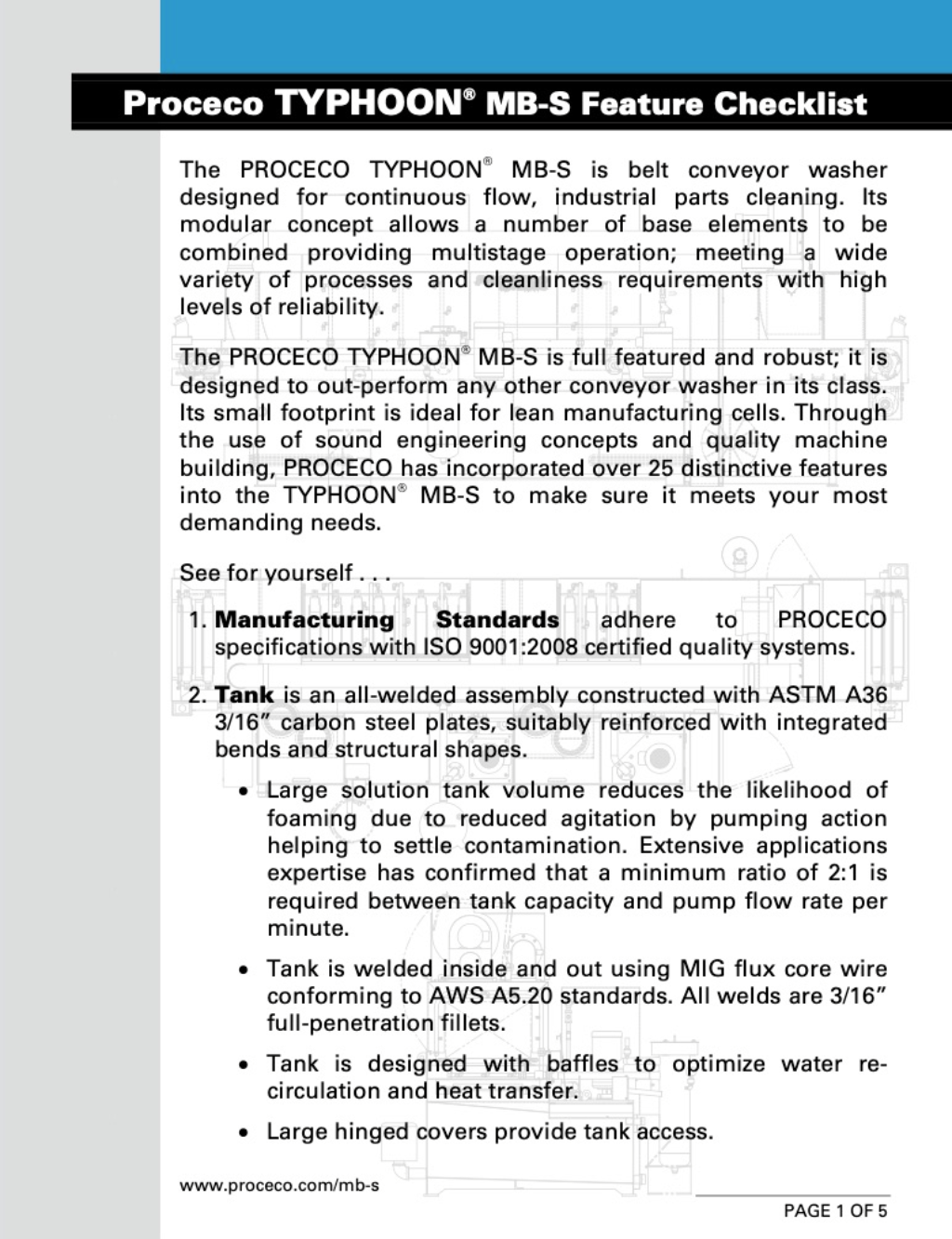

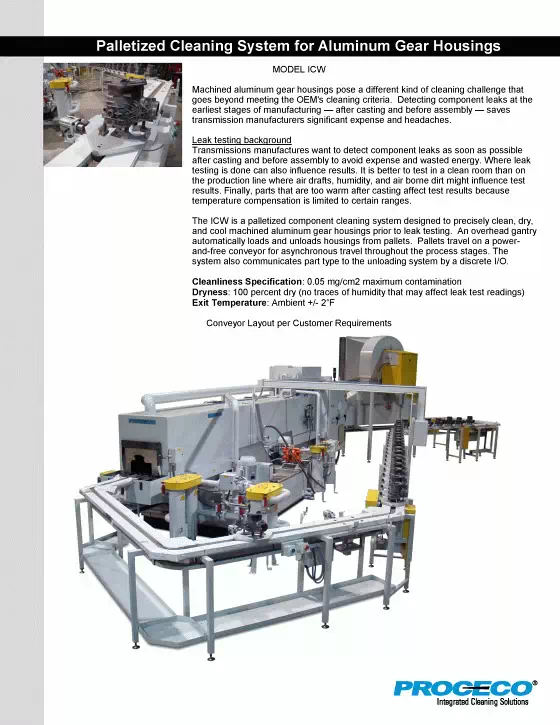

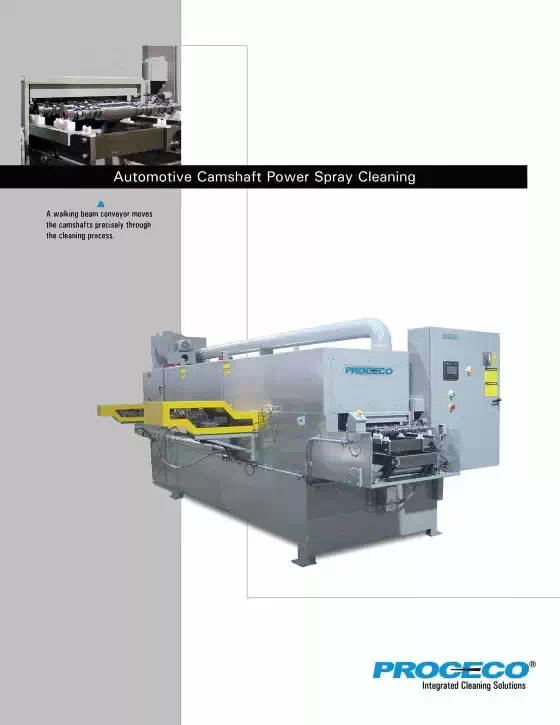

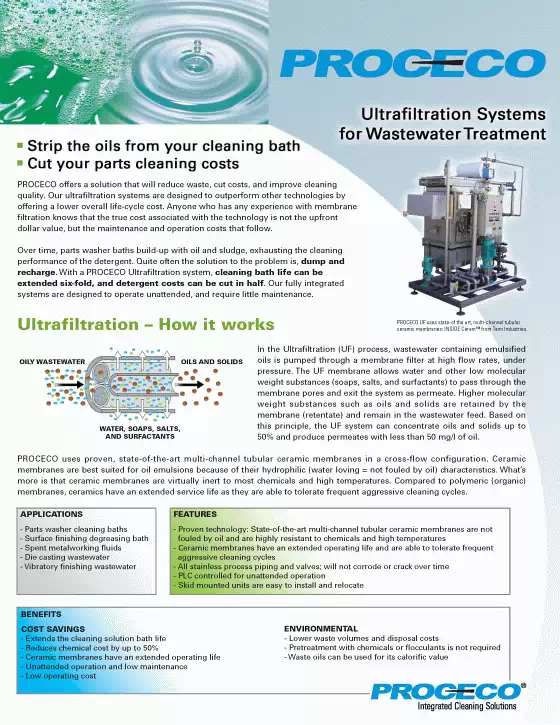

PROCECO develops aqueous cleaning systems that go beyond cleaning, by seamlessly integrating a wide range of processes and features that dramatically improve your productivity and profitability.