Slurry Blaster Equipment - Spinner Hanger

Key benefits

- Patented slurry blasting technology

- No dust or need for a dust collector

- Fast cycle times

- Degrease, blast clean, aqueous clean, and inhibit rust, all in one system

- The process produces a very clean and smooth surface finish

- Integrated sludge removal conveyor prolongs solution life

Overview

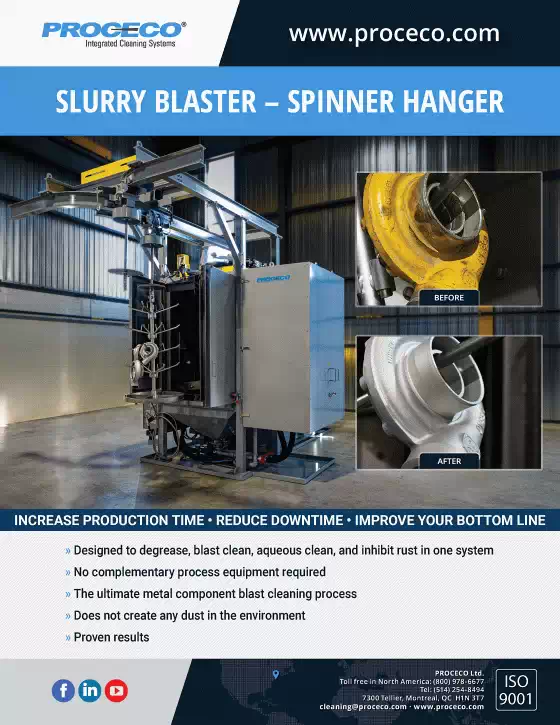

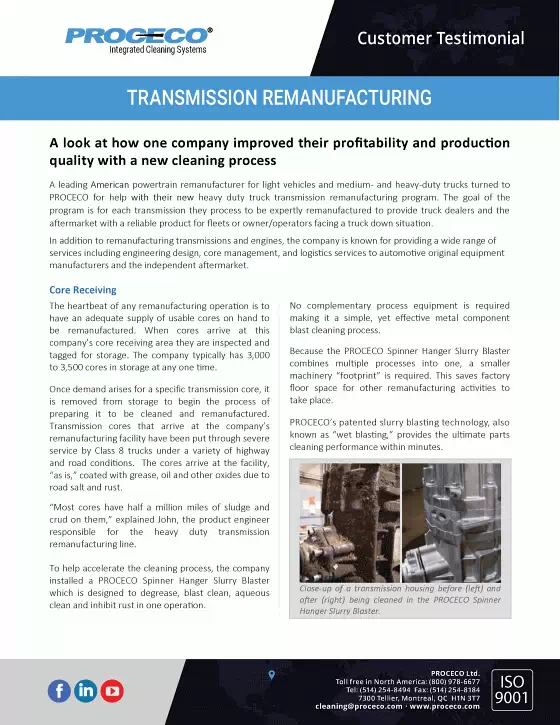

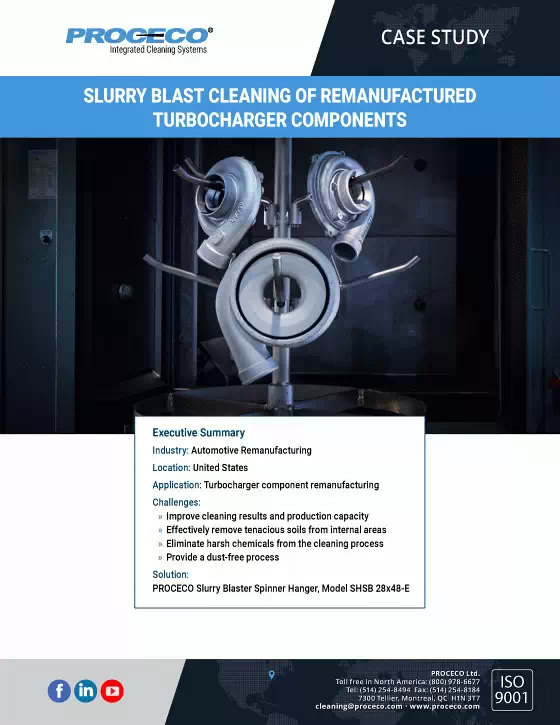

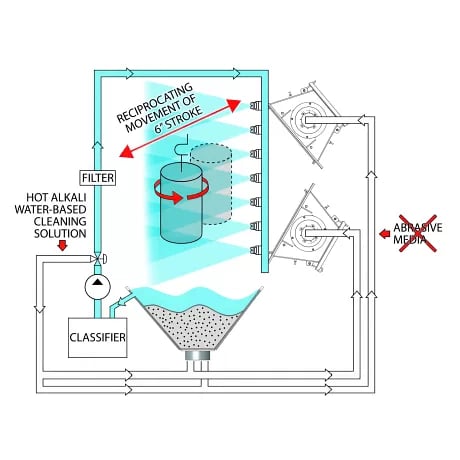

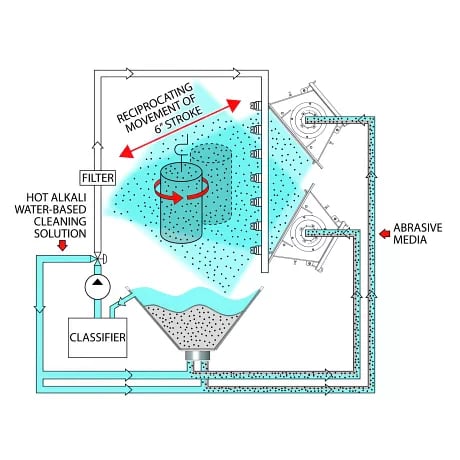

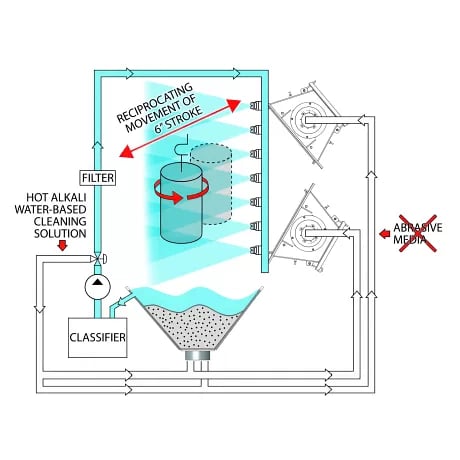

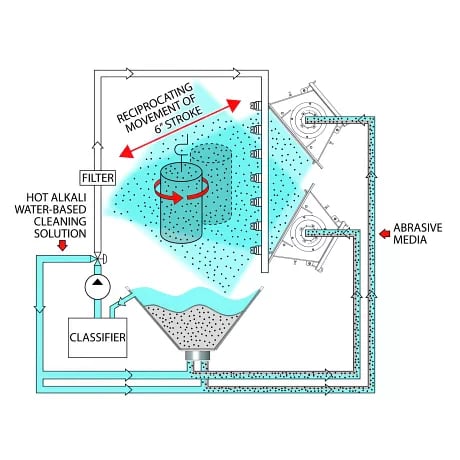

Designed to degrease, blast clean, aqueous clean, and inhibit rust in one system — with no complementary process equipment required — the PROCECO Slurry Blaster Spinner Hanger is the ultimate metal component blast cleaning process. In addition, slurry blasting does not create any dust in the environment.

The Spinner Hanger model automatically processes a single large part or batches of parts of various sizes loaded onto a custom-designed holding fixture. A hook rotates and reciprocates the loaded part/fixture back and forth to expose all surfaces to the cleaning solution and the accelerated abrasive slurry. This combination of rotation and oscillation in front of the slurry blast pattern ensures uniform, thorough coverage of geometrically complex components.

A programmable controller monitors the process and allows for the selection of pre-programmed cycle times for any of the components to be cleaned.

- Specification sheets

- Download resources

- Videos

-

Work HeightWork Height42”48”56”60”72”84”108”

-

TESTIMONIALS

The installation was a success [...] Proceco Provided two machines on-site in a very timely, well-organized, and cost-efficient manner.

Thank you for all of the hard work. I look forward to working with Proceco again in the future on any other cleaning endeavors.

Joshua D. Gore

“.... we immediately ran our product through it. The results were outstanding. It cleaned the product so well that we will actually use a shorter cycle time than what we had anticipated...”

Curtis Malone

CONTACT A SOLUTION EXPERT

PROCECO develops aqueous cleaning systems that go beyond cleaning, by seamlessly integrating a wide range of processes and features that dramatically improve your productivity and profitability.